The fashion industry's shift toward circularity reached a milestone with H&M Group's expanded partnership with textile recycling innovator Circulose® – a deal accelerating demand for next-gen regenerated materials. As a leading T2T (textile-to-textile) materials supplier, Yooretex recognizes this collaboration as critical infrastructure evolution – transforming millions of garments into premium regenerated fibers through science-driven innovation.

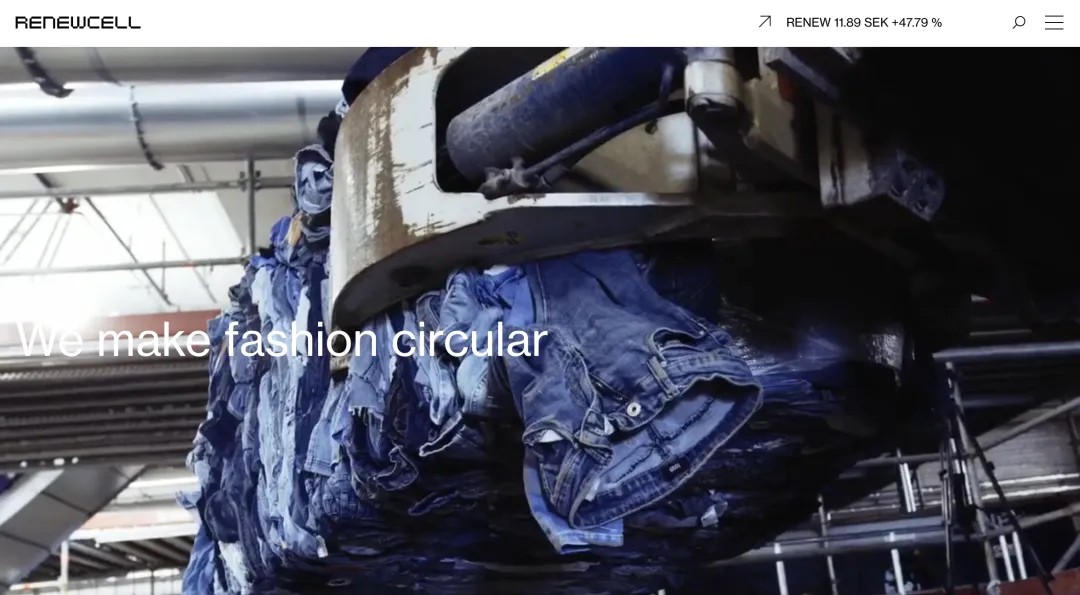

The Circulose Innovation: Turning Rags into Resources

H&M's 2020-2024 collections containing regenerated fabrics demonstrate these technical milestones are achievable through skilled T2T recycling manufacturing.

Key breakthroughs:

1

Patented chemical recycling process removing dyes/polyester blends

2

100% textile-derived cellulose output (no wood pulp blending)

3

Licensing model enabling scaling (per Fashion for Good/Canopy frameworks)

Yooretex: Engineering Recycled Pulp into Premium Textiles-As Circulose's downstream manufacturing partner, Yooretex bridges the gap between fiber innovation and commercial textiles:

1️⃣ Input: Receiving Circulose's regenerated cellulose pulp

2️⃣ Transformation: Spinning pulp into viscose/lyocell fiber yarns

3️⃣ Output: Weaving/knitting yarns into high-quality regenerated materials (fabrics, synthetics)

4️⃣ Supply: Delivering circular textiles to brands like H&M Group

This technical symbiosis closes fashion's loop: Textile recycling collection → Circulose pulp → Yooretex's regenerated fibers → fashion brands = new textile recycling circular collections.

Why Textile Recycling Partnerships Matter

The H&M Group's landmark multi-year partnership with Circulose marks a pivotal leap in textile recycling scalability. Yooretex champions Circulose's partnership model as textile recycling's growth accelerator. As Janmark states: "We need more brands to join this movement."