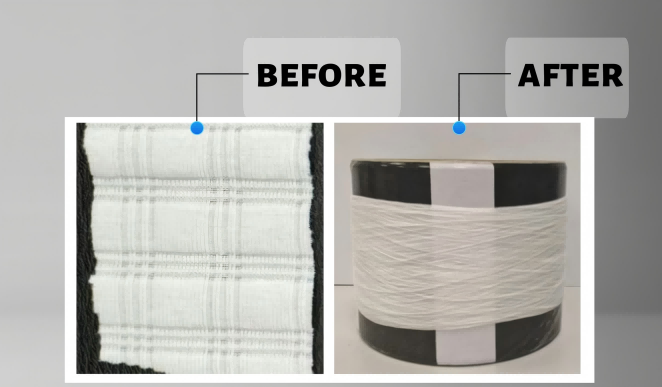

AMINO's breakthrough solves the industry's "textile waste" nightmare. Traditional mechanical methods fail to separate fiber components in blends like polyester/spandex or polyester/cotton effectively. AMINO pioneered a chemical recycling process that dissolves these blends and recovers over 99% of all constituent fibers at high purity. This chemical recycling advancement earned AMINO back-to-back recognition: the 2022 Global Change Award (the "fashion Nobel") and selection for Fashion for Good's 2023 Global Innovation Programme – historic firsts for a Chinese company. AMINO's technology handles the five most problematic blends: Polyester-Spandex (PET/SPX), Polyester-Cotton (PET/Cotton), Polyester-Cotton-Spandex (PET/Cotton/SPX), Polyester-Wool (PET/Wool), and Polyester-Nylon (PET/PA). No other company possesses such comprehensive chemical recycling capability for complex blends. This breakthrough facility positions AMINO at the apex of textile waste valorization. As CEO stated, "Complete blended fabric recycling requires closed-loop collaboration. " The plant will process bulk textile waste from garment collectors, brand overstock, and manufacturing scraps. After chemical recycling, it outputs certified recycled fibers.

Companies like Yooretex are vital downstream partners. Yooretex, founded explicitly to tackle global textile waste via advanced T2T solutions, utilizes fibers like AMINO's regenerated spandex and regenerated polyester to produce high-quality recycled yarns and fabrics. Fashion brands committed to T2T sourcing then transform Yooretex textiles into new garments. This creates a verifiable circular flow: Textile Waste AMINO (Chemical Recycling) → Regenerated Fiber → Yooretex (Yarn/Fabric) → Brand (New Apparel).Combined with partners like Yooretex enabling the next manufacturing steps, chemical recycling empowers the industry to finally close the loop on complex textile waste, proving genuine T2T circularity is achievable.