The Golisano Institute for Sustainability (GIS) at Rochester Institute of Technology pioneers textile recycling automation technology capable of processing complex post-consumer garments — a critical advancement for scaling circular T2T processing. Funded by REMADE Institute with Nike, Goodwill, and Ambercycle support, this AI and laser-based system addresses the core barrier in textile recycling: inconsistent composition.

The Problem: Contaminated Post-Consumer Waste

Over 11 million tons of textiles enter US landfills yearly. Most are discarded post-consumer garments containing zippers, prints, tags, and blended materials — rendering manual recycling economically unviable. Traditional textile recycling automation handles predictable industrial scrap but falters with diverse consumer waste. Yooretex believes GIS's innovation finally bridges the gap between laboratory-scale circularity and industrial textile recycling automation.

How the Technology Works

1

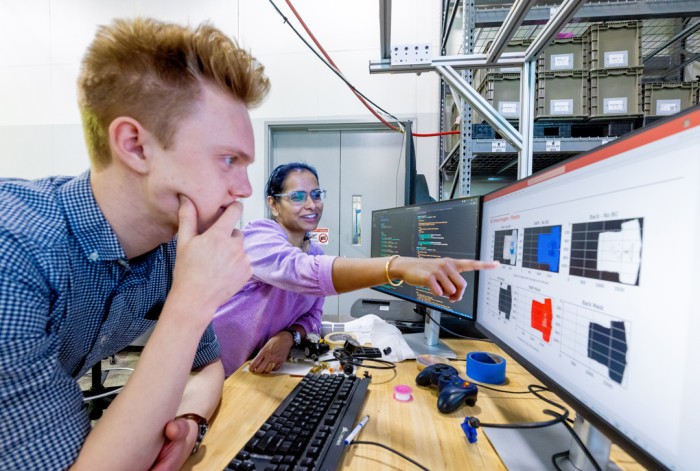

AI Vision Scanning:

3-camera conveyor system captures garments at millimeter resolution;

Algorithms detect collars, cuffs, and logos using infrared spectroscopy.

2

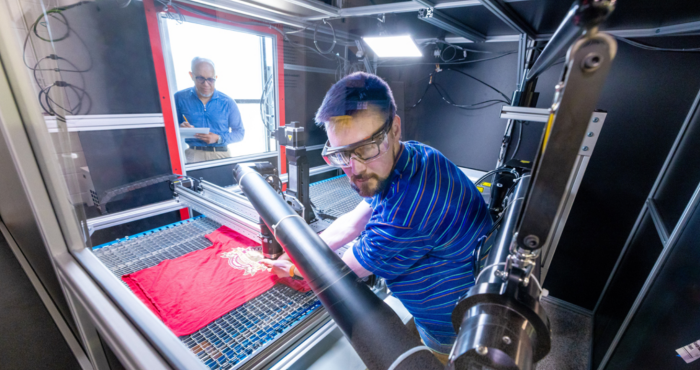

Laser Precision Removal:

Robotic lasers excise non-recyclable elements without damaging fabrics.

3

Automated Sorting:

Clean materials routed to dedicated recycling streams;

Processes one garment every 10 seconds.

"Unlike manufacturing where parts are predictable, every post-consumer garment is unique," states AI developer Md Shahidul Islam. "Our vision-guided systems make real-time decisions – a revolution in textile recycling automation.”

Industry Backing & Scalable Design

Dr. Volker Sick, technical lead, emphasizes scalability: "This T2T processing solution won't eliminate global waste alone, but it makes post-consumer garments economically attractive feedstock – avoiding landfills by turning complexity into opportunity."