Revolutionizing Textiles The Shift from Open-Loop to Closed-Loop for Zero Waste

International Day of Zero Waste

March 30th this year is the third International Day of Zero Waste. On December 14, 2022, the 77th United Nations General Assembly passed Resolution 77/161, declaring March 30 of each year as International Zero Waste Day.

This International Day aims to draw global attention to the various impacts of waste generation, reflect on our practices, and encourage action at all levels to reduce pollution and waste, embrace a circular economy, and reduce resource use and environmental emissions at all stages of the product lifecycle.

Global Recycling Day

As early as March 18, 2018, the Bureau of International Recycling (BIR) announced the establishment and celebration of the first "Global Recycling Day" ahead of the United Nations. This day is also the 70th anniversary of BIR's creation.

Global Recycling Day aims to raise public awareness of the seventh resource, "recycled resources," in addition to the six major natural resources of water, air, coal, oil, natural gas, and mineral resources. It helps people realize the importance of recycling in preserving the Earth's precious primary resources and ensuring its future development.

Regenerated fiber enterprises all point to a common concept - "fiber to fiber recycling" or "textile to textile", that is, "closed-loop recycling".

Upgrade from "open-loop recycling" to "closed-loop recycling"

At present, most of the "recycled/reclaimed" concept products available to consumers in the market are based on the "physical method" technology that has been industrialized for more than a decade, known as "bottle to fiber recycling" or "open loop recycling".

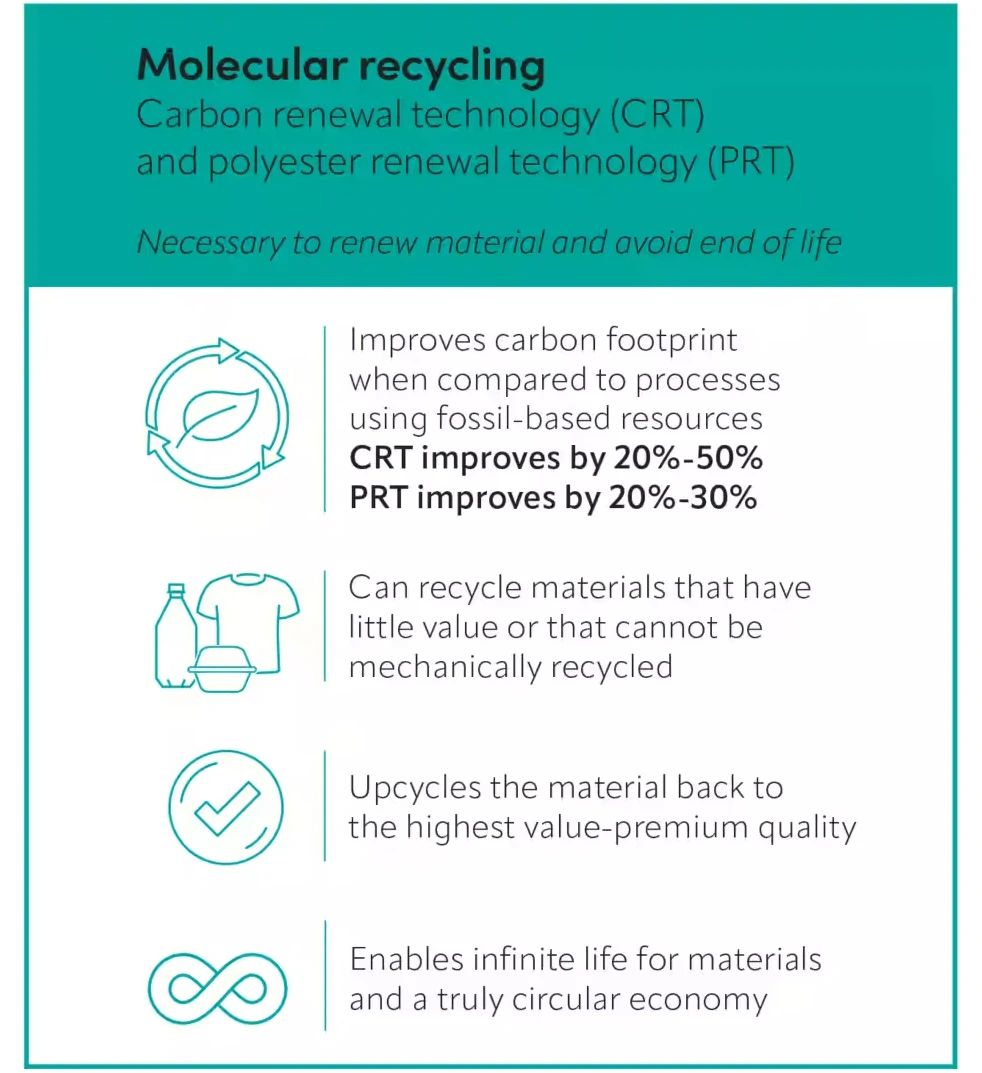

The main enterprises that can truly help the textile industry achieve "closed-loop recycling" are those that have mastered the "chemical method" technology. In just 24 years, American company Eastman announced plans to establish the second low-carbon recycled PET plant in the United States in Texas. After completion, the factory can process 110000 tons of waste PET annually, and the produced recycled PET can reduce carbon emissions by more than 70% compared to native PET.