Regulatory Pressure: A Turning Point for Circular Economy

1

Eco-Design Regulation (ESPR):

Effective June 2024, ESPR mandates durable, repairable, and recyclable product designs by 2030. It also prohibits destroying unsold goods.

2

Extended Producer Responsibility (EPR):

Starting January 2025, brands must establish independent textile recycling systems, eliminating incineration and landfill disposal.

3

Packaging and Packaging Waste Regulation (PPWR):

To enforce a unified recycled materials market by August 2026, brands must track packaging waste and integrate circular principles.

4

Behind these policies lies a stark reality:

80% of global textile waste remains unrecycled, underscoring urgent need for circular economy infrastructure.

Strategic Responses: Pioneering Circular Innovations

1. Self-Built Platforms for Material Reuse

HUGO BOSS's Eightyards: Launched in 2025, this subsidiary repurposes surplus fabrics into new products.

Its B2B marketplace sells premium deadstock materials, targeting cross-industry textile recycling.

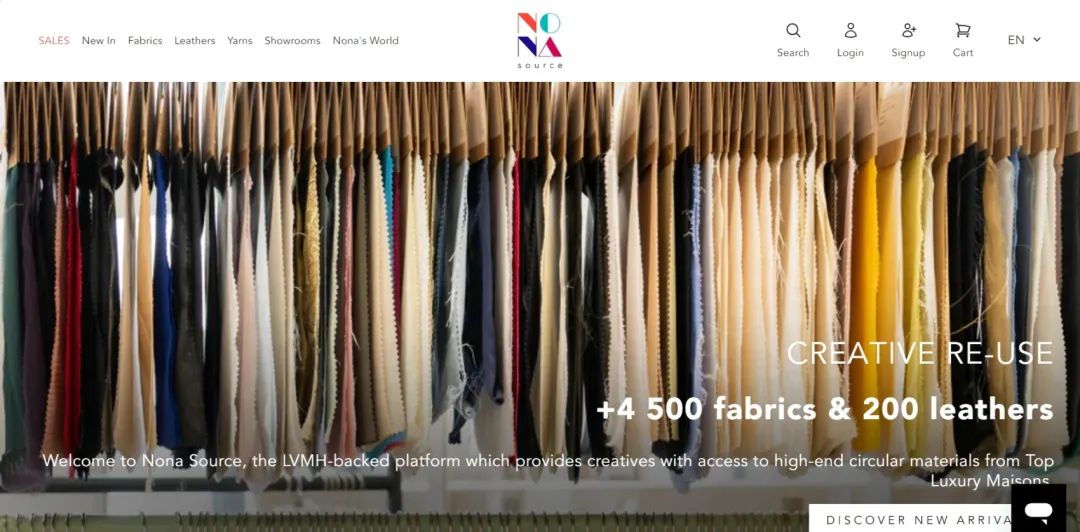

LVMH's Nona Source: This platform sells unused luxury fabrics (e.g., silk, leather) at reduced costs, excluding brand logos.

2. Investing in Textile Recycling Startups

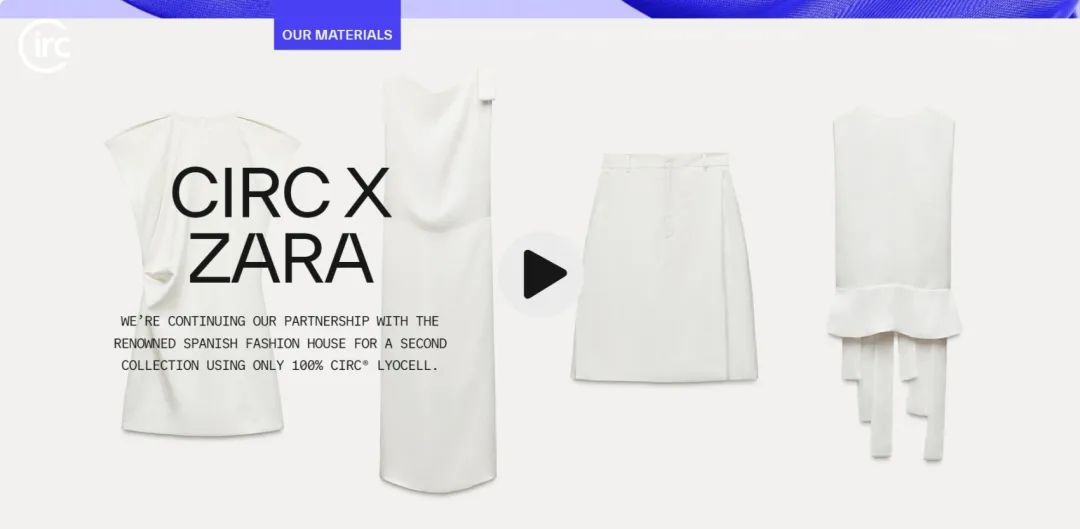

Zara's Partnership with Circ: Circ's patented technology recycles polyester-cotton blends into Circ® Lyocell fibers.

Its first industrial plant aims to recycle 300K tons/year by 2028.

H&M's Syre Collaboration: Syre plans 12 global plants to produce 3M tons/year of recycled polyester.

H&M's $600M deal ensures long-term sustainable material sourcing.

Lululemon & Samsara Eco: Using enzymatic recycling, Samsara breaks down nylon 66 and polyester into virgin-grade materials without fossil fuels.

The Future of Textile Recycling

Europe's regulatory storm is accelerating the shift from linear to circular economy models. Companies that prioritize textile recycling, invest in enzymatic technologies, and adopt eco-design principles will thrive. For QUANZHOU YOORE NEW MATERIAL CO., LTD, this transformation offers unparalleled opportunities to supply T2T fabrics and shape a waste-free future. The fusion of EU regulations, circular innovations, and Circular Economy sustainable materials isn't just eco-compliance—it's the blueprint for tomorrow's fashion industry.